Our Block Manufacturing Process

The production of concrete blocks consists of four basic processes: mixing, molding, curing, and cubing.

Mixing

The sand and gravel are transferred by an elevator up into bins, that are stored inside. The portland cement is stored outside in a large vertical silo to protect it from moisture.

As the production begins, the sand and gravel are gravity fed into the weigh batcher which measures the proper amount of each material.

The dry materials then flow into the mixer, which blends them together with a small amount of water, for several minutes. This "dry mix" is now easy to manipulate and ready to be molded. At this point the mixing cycle starts again.

Molding

The "dry mix" is empied out of the mixer, and elevated by conveyer into a hopper above the block machine. The mix is forced downward into the molds. The size of the mold, determines the size of the block. Our machine can produce two 12" block at a time or, by switching the mold, six 4" block at a time. When the molds are full, the concrete is compacted, or pressed by the machines upper mold head. The concrete is pressed and vibrated vigorously to avoid holes or air pockets. The pressed blocks are forced out of the molds onto steel pallets and driven, by conveyer, to the kiln.

.jpg)

Curing

The kiln is an enclosed room with an operating temperature of around 150 degrees and able to hold around 10,000 blocks at a time. The blocks move into the kiln at a steady rate coming out of the block machine and stay here to cure in the hot, moist air for 12 - 16 hours. In kiln, the temperatures, pressures, and cycle times are all controlled and recorded automatically to ensure that the blocks are cured properly, in order to achieve their required strength.

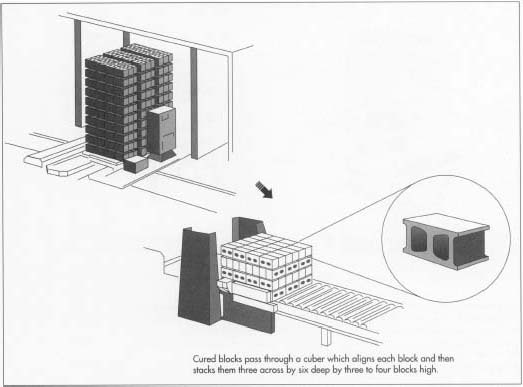

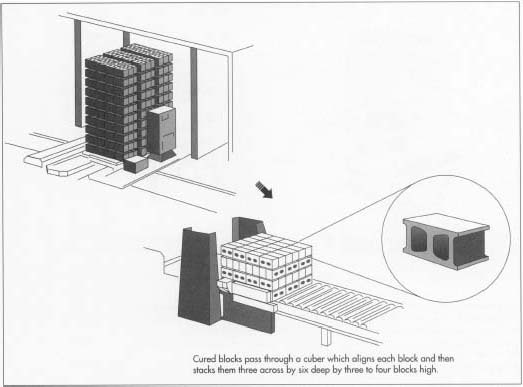

Cubing

The cured blocks roll out of the kiln and are pushed off their steel pallets. The blocks pass through a cuber which aligns each block and then stacks them into a cube 3 blocks across, 5 blocks deep and 4 or 5 blocks high. These cubes are then carried outside with a forklift and placed in storage.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)